-

Rulment JDB solid-lubrifiant Bucșă de rulment cu ghidaj al flanșei ejectorului fără ulei din alamă JGBF

Rulment JDB solid-lubrifiant Bucșă de rulment cu ghidaj al flanșei ejectorului fără ulei din alamă JGBF -

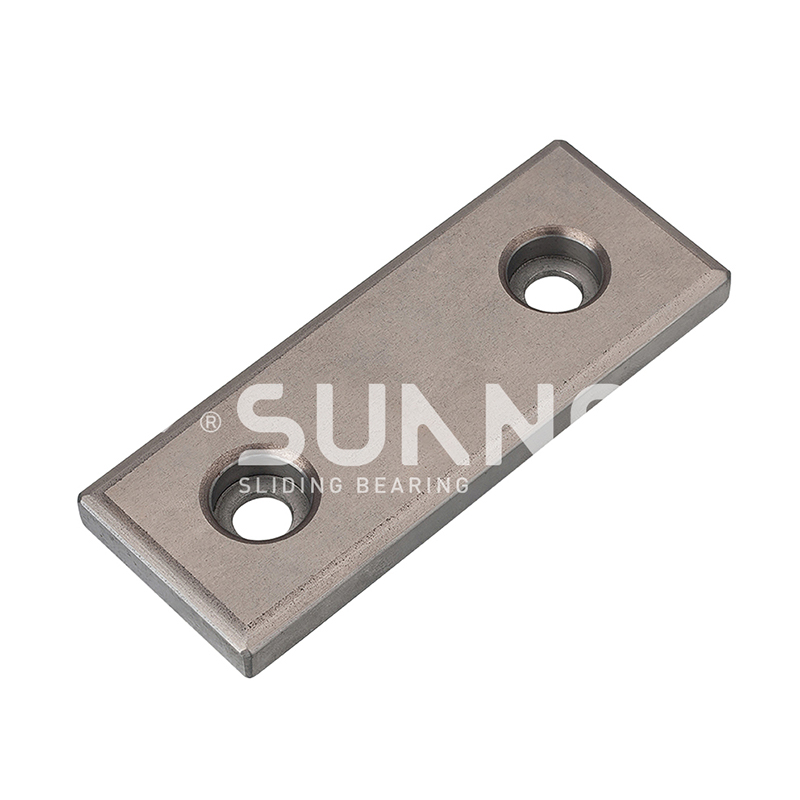

Rulment bimetalic de reținere a uleiului Placă de uzură de reținere a uleiului 200#P10 - Rulment de încărcare mare, placă de oțel cu frecare scăzută pentru aplicații industriale

Rulment bimetalic de reținere a uleiului Placă de uzură de reținere a uleiului 200#P10 - Rulment de încărcare mare, placă de oțel cu frecare scăzută pentru aplicații industriale -

-

-

Rulment bi-metal JF-800 JF-700 Bi-metal purtând cu mânecă cu mânecă auto-latubrică

Rulment bi-metal JF-800 JF-700 Bi-metal purtând cu mânecă cu mânecă auto-latubrică -

Rulment învelit de bronz FB090 Rulment învelit de bronz FB090

Rulment învelit de bronz FB090 Rulment învelit de bronz FB090 -

Rulment învelit de bronz FB090 FB092 Rulmar învelit în bronz

Rulment învelit de bronz FB090 FB092 Rulmar învelit în bronz -

Rulment învelit de bronz FB090 FB094 Rulmar învelit din bronz cu garnituri

Rulment învelit de bronz FB090 FB094 Rulmar învelit din bronz cu garnituri

Înțelegerea rulmenților SF-1 Oilless: Caracteristici și aplicații cheie

Știri din industrie-SF-1 Oilless Rulment vs Bushings Bronz: o analiză comparativă

Când selectați rulmenți pentru utilaje, alegerea dintre SF-1 rulmenți și bucșele tradiționale de bronz apar adesea. Înțelegerea diferențelor lor ajută la luarea unei decizii în cunoștință de cauză.

1. Compoziția materială și durabilitatea

SF-1 rulmenți sunt de obicei fabricate dintr-un material compozit format dintr-un suport de oțel, un strat sinterizat de bronz poros și o suprafață pe bază de PTFE. Această construcție oferă o rezistență excelentă la uzură și reduce frecarea. În schimb, bucșele de bronz sunt componente metalice solide, de obicei realizate din aliaje precum C93200 sau C95400, care se bazează pe lubrifierea externă pentru a minimiza uzura.

În timp ce bucșele de bronz sunt robuste, acestea necesită un lubrifiere frecventă, în timp ce SF-1 rulmenți sunt concepute pentru a funcționa fără lubrifiere suplimentară datorită proprietăților lor auto-lubrifiante. This makes them more durable in environments where maintenance is challenging.

SF-1P Motion Reciprocing Bronz Bushing compozit auto-lubrifiat

2. Rezistența la frecare și uzură

Stratul PTFE în SF-1 oilless bearings significantly reduces friction, making them ideal for high-speed applications. Bronze bushings, on the other hand, exhibit higher friction coefficients, especially if lubrication is inadequate.

Mai jos este o comparație a coeficienților de frecare:

| Proprietate | SF-1 Oilless Bearing | Bronze Bushing |

|---|---|---|

| Friction Coefficient (Dry) | 0.05 - 0.15 | 0,20 - 0,40 |

| Wear Rate | Scăzut | Moderate to High |

3. Întreținere și durată de viață

SF-1 oilless bearings require minimal maintenance, whereas bronze bushings need regular lubrication to prevent premature failure. In dusty or high-temperature environments, bronze bushings may fail faster due to lubricant degradation.

SF-1 Oilless Bearing Temperature Range and Performance

1. Optimal Operating Temperatures

SF-1 oilless bearing temperature range typically spans from -40°C to 250°C, making them suitable for both extreme cold and moderate heat. ir PTFE layer remains stable across this range, ensuring consistent performance.

2. Effects of High and Low Temperatures

At high temperatures, traditional lubricants in bronze bushings can evaporate or degrade, leading to increased friction. SF-1 oilless bearings , however, maintain their lubricity due to the embedded solid lubricants.

3. rmal Expansion Considerations

Thermal expansion is minimal in SF-1 oilless bearings due to their composite structure, whereas bronze bushings may expand more, affecting fit and performance.

SF-1 Oilless Bearing Load Capacity Explained

1. Static vs Dynamic Load Ratings

The SF-1 oilless bearing load capacity is impressive, with static load ratings up to 250 MPa and dynamic load ratings around 140 MPa. This makes them suitable for heavy-duty applications.

2. Factors Affecting Load Capacity

Load capacity depends on alignment, speed, and temperature. Misalignment can reduce lifespan, while proper installation maximizes performance.

3. Comparing Load Handling with Other Bearings

Compared to plastic bearings, SF-1 oilless bearings handle higher loads, but they may not match the extreme load capacity of some hydrostatic bearings.

SF-1 Oilless Bearing Lubrication Requirements

1. Self-Lubricating Mechanism

The SF-1 oilless bearing lubrication requirements are minimal due to the PTFE and lead-infused surface, which provides continuous lubrication.

2. When Additional Lubrication Might Be Needed

In extremely high-load or high-speed scenarios, supplemental lubrication may extend lifespan, though it's rarely necessary.

3. Environmental Impact of Lubrication-Free Design

Eliminating oil or grease reduces contamination risks, making SF-1 oilless bearings eco-friendly.

SF-1 Oilless Bearing Applications in Industrial Machinery

1. Common Industrial Use Cases

These bearings excel in conveyor systems, packaging machines, and agricultural equipment due to their durability and low maintenance.

2. Advantages Over Traditional Bearings in Heavy Machinery

Unlike lubricated bearings, SF-1 oilless bearings won't fail due to lubricant starvation, making them ideal for remote or harsh environments.

3. Future Trends in Oilless Bearing Adoption

As industries move toward maintenance-free solutions, SF-1 oilless bearings are becoming a preferred choice for reliability and cost-efficiency.