-

Rulment JDB solid-lubrifiant Rulment ghidaj ejector fără ulei din alamă pentru temperaturi înalte JGB

Rulment JDB solid-lubrifiant Rulment ghidaj ejector fără ulei din alamă pentru temperaturi înalte JGB -

Rulment JDB solid-lubrifiant GB71 NAAMS flanșă bucșă tip umăr rulment standard cu lubrifiere solidă

Rulment JDB solid-lubrifiant GB71 NAAMS flanșă bucșă tip umăr rulment standard cu lubrifiere solidă -

Rulment JDB solid-lubrifiant GB61 Bronz NAAMS Rulmenți de lubrifiere solidă cu flanșă standard

Rulment JDB solid-lubrifiant GB61 Bronz NAAMS Rulmenți de lubrifiere solidă cu flanșă standard -

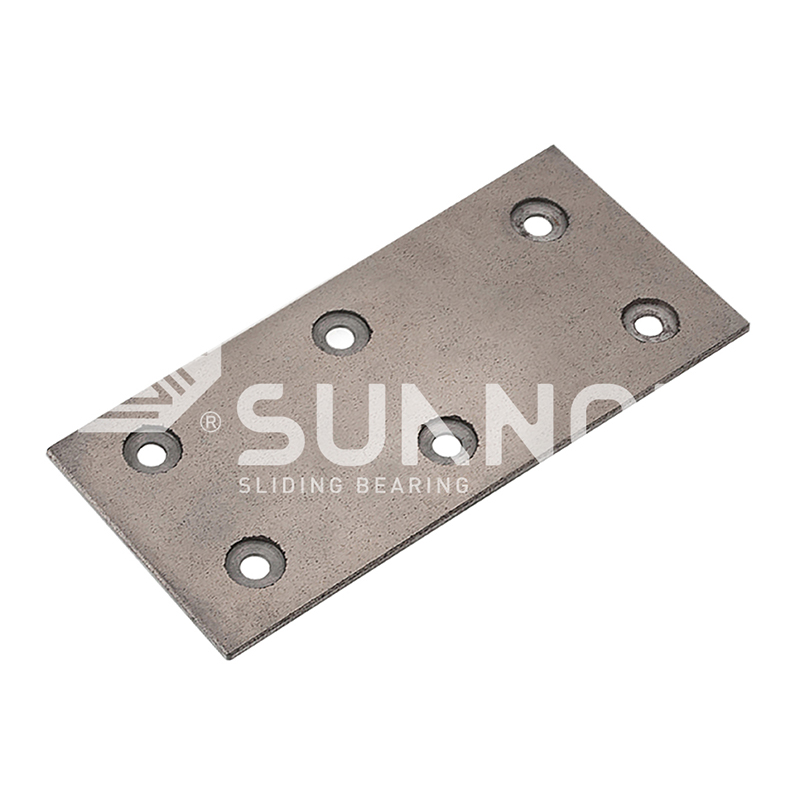

Rulment JDB solid-lubrifiant JTWP Nu este nevoie de ulei Rezistență la uzură Zero Întreținere Oilless Placă de uzură

Rulment JDB solid-lubrifiant JTWP Nu este nevoie de ulei Rezistență la uzură Zero Întreținere Oilless Placă de uzură -

Rulment bimetalic de reținere a uleiului Placă de rulment cu oțel care menține ulei de apă de 2# P20-Rezistent la uzură cu frecare scăzută

Rulment bimetalic de reținere a uleiului Placă de rulment cu oțel care menține ulei de apă de 2# P20-Rezistent la uzură cu frecare scăzută -

Rulment bimetalic de reținere a uleiului 200#P5 P5 Placă de uzură auto-lubrifiantă-suprafață de rulment cu frecare scăzută

Rulment bimetalic de reținere a uleiului 200#P5 P5 Placă de uzură auto-lubrifiantă-suprafață de rulment cu frecare scăzută -

-

Rulment bi-metal JF-800 JF-750 Auto-lubrifiant Lead Bi-Metal Bi-Metal pentru motoare grele Friction scăzut

Rulment bi-metal JF-800 JF-750 Auto-lubrifiant Lead Bi-Metal Bi-Metal pentru motoare grele Friction scăzut

Care sunt caracteristicile cererii automatizării industriale pentru rulmenți de lubrifiant solid?

Știri din industrie-Cererea pentru Rulmenți de lubrifiant solid in the field of industrial automation has unique characteristics, which are mainly derived from the requirements of automation equipment for high precision, high reliability, low maintenance and clean operation. Următoarele sunt mai multe caracteristici cheie ale cererii automatizării industriale pentru rulmenți de lubrifiant solid:

JGBF Brass Oilless Ejector Ghid Flanged Bushings Bushings

1.. Precizie ridicată și fiabilitate ridicată

Industrial automation equipment (such as robots, automated production lines, and precision machining centers) needs to maintain high precision and high reliability for a long time. Avantajele rulmenților de lubrifiant solid în aceste aplicații includ:

High precision: solid lubricant bearings can provide stable rotational motion, reduce vibration and friction, and ensure the processing accuracy and motion accuracy of the equipment.

High reliability: solid lubricant bearings use self-lubricating materials, which reduces the risk of failure caused by insufficient lubricant or contamination, and improves the reliability of the equipment.

Long life: solid lubricant materials (such as graphite, molybdenum disulfide, etc.) have excellent wear resistance, can operate stably for a long time in harsh environments, and reduce the frequency of bearing replacement.

2.. Întreținere scăzută și funcționare curată

Automation equipment usually needs to run for a long time without human intervention, so the maintenance requirements for bearings are extremely high. Caracteristicile rulmenților de lubrifiant solid includ:

Low maintenance requirements: Solid lubricant bearings do not require regular addition of lubricants, reducing maintenance workload and downtime.

Clean operation: Since liquid lubricants are not used, solid lubricant bearings will not leak oil and avoid pollution to equipment and production environment, especially suitable for industries such as food processing, pharmaceuticals and electronic manufacturing.

Pollution resistance: Solid lubricants have high tolerance to dust, debris and chemicals, and can maintain stable performance even in polluted environments.

3. Adaptați -vă la condiții de muncă complexe

Industrial automation equipment usually operates under complex working conditions, and solid lubricant bearings need to have the following characteristics:

High and low temperature resistance: Able to operate stably at extreme temperatures (such as -40℃ to 200℃), suitable for high temperature furnaces, cold storage and other environments.

Corrosion resistance: Solid lubricants (such as polytetrafluoroethylene) have good corrosion resistance to chemicals and are suitable for corrosive environments.

Capacitate ridicată de încărcare: capabil să reziste la sarcini mari și viteze mari, adecvate pentru echipamente grele de utilaje și de prelucrare de înaltă precizie.

Impact resistance: Solid lubricating bearings can remain stable under high impact loads and are suitable for robot joints and automated production lines.

4. Miniaturizare și ușoară

As industrial automation equipment develops towards miniaturization, lightweight and high performance, solid lubricating bearings also need to meet the following requirements:

Miniaturization design: Suitable for small robots, micro motors and precision instruments, etc., and can provide high performance in a limited space.

Lightweight materials: Solid lubricating bearings are made of lightweight materials (such as high-performance plastics and composite materials) to reduce equipment weight and improve energy efficiency.

5. Integrare inteligentă

Modern industrial automation equipment is increasingly dependent on intelligent technology, and solid lubricating bearings also need to be integrated with intelligent systems:

Condition monitoring function: Integrated sensors and monitoring systems to monitor the operating status of bearings (such as temperature, vibration, wear degree) in real time to achieve predictive maintenance.

Adaptive lubrication: Through intelligent control systems, lubrication performance is automatically adjusted according to the operating status of the equipment to extend the life of the bearing.

Remote monitoring: Support remote monitoring and fault diagnosis, reduce on-site maintenance workload, and improve equipment operation efficiency.

6. Personalizare și compatibilitate

Diversitatea și complexitatea echipamentelor de automatizare industrială necesită rulmenți de ungere solidă pentru a avea următoarele caracteristici:

Customized design: It can be customized according to the specific needs of the equipment (such as size, shape, load type) to meet personalized needs.

Compatibility: Solid lubrication bearings need to be compatible with existing automation equipment and control systems for easy installation and integration.